At Alloyed, we understand that making the right decisions while moving quickly requires efficient processes and excellent use of data

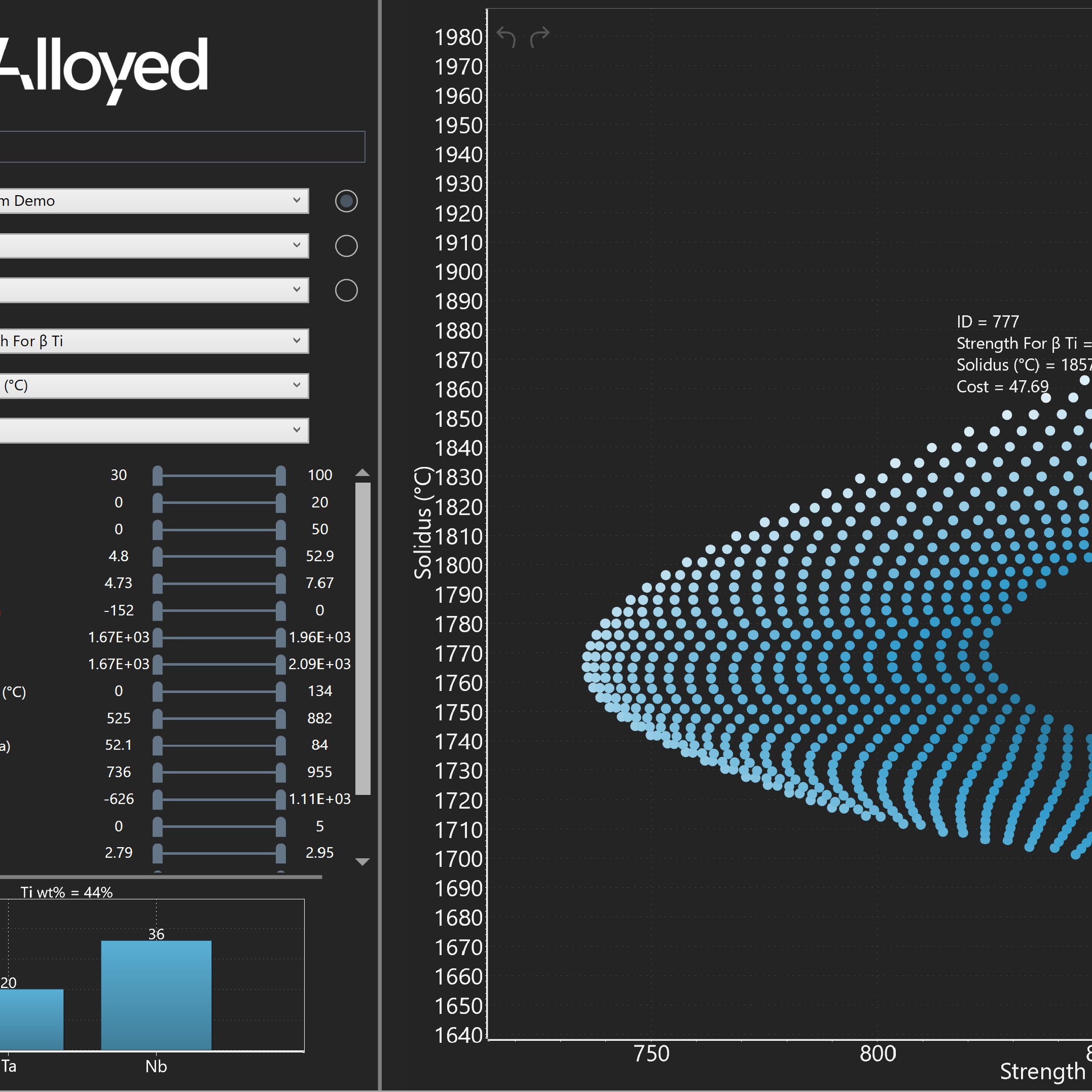

We develop our own technology suite of intelligent, intuitive and integrated platforms for unrivalled processes and materials.

Every part we build and test presents an opportunity to capture insightful data, but effectively harnessing this data is key. Our PDS function drives development of our data management platform, ensuring data is centrally stored and easily accessible. We use this data to train a suite of predictive models that accelerate development across all areas of the business, from alloy design to process improvement and automation. Our approach is physics-informed and data-driven, making the best use of our combined wealth of metallurgical expertise and data-generation capability.