Our Capabilities

Alloyed has extensive experience in developing optimised aluminium alloys and aluminium metal matrix composites using the ABD® platform. Our platform incorporates hundreds of metallurgical models applicable to aluminium systems, which allows for prediction and optimisation of both alloy performance and cost for a wide range of potential compositions.

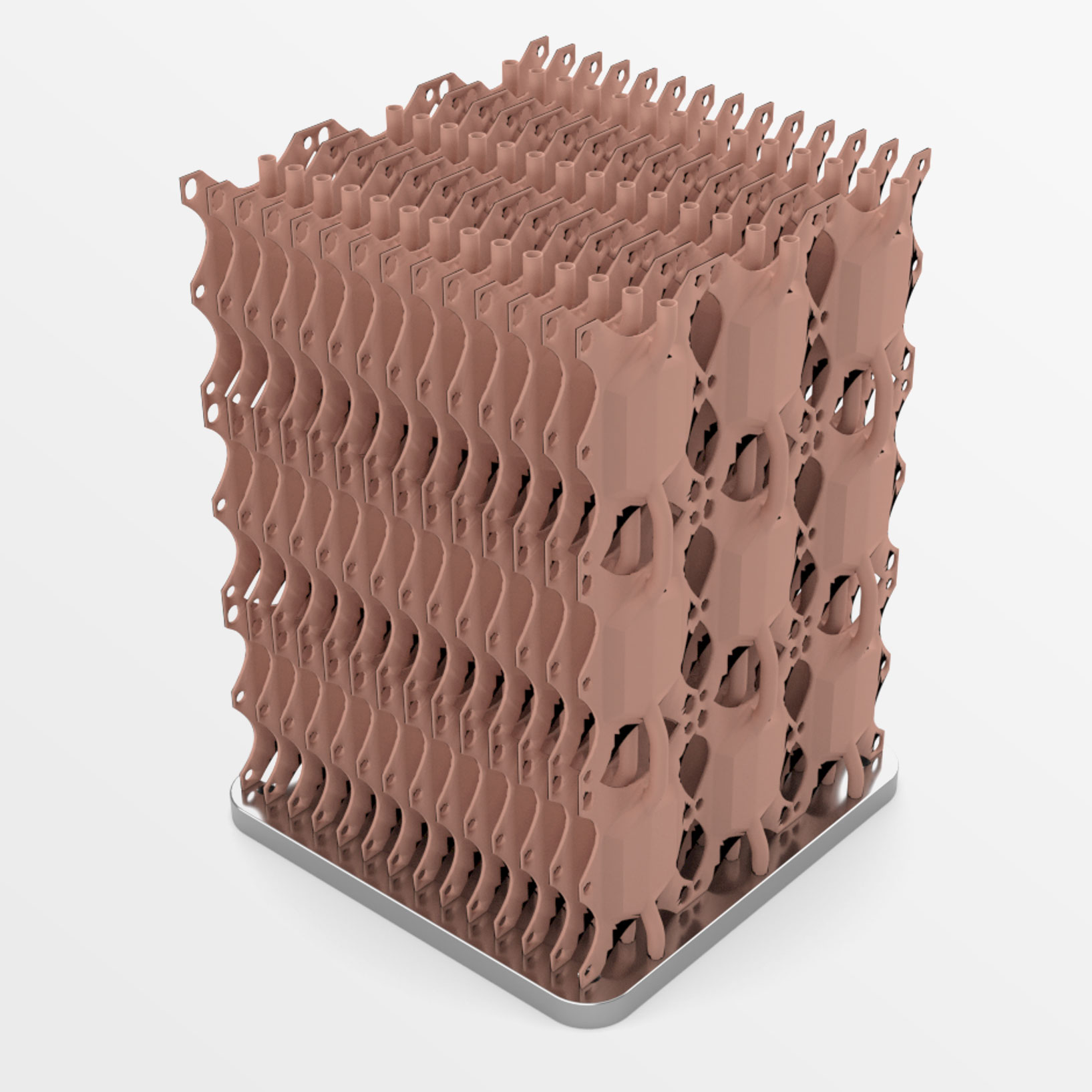

Post-processing requirements can also be accommodated, including heat treatment optimization for new or existing alloys. This process can be achieved in weeks rather than years and the aluminium alloys can be tailored specifically for the manufacturing process — whether that is casting, forming or AM. Our computational platform is backed by state-of-the-art experimental facilities which allow us to fabricate, process and evaluate any aluminium at lab-scale, which is a crucial step in the development and validation of our computational models.