Alloyed specialises in custom orthopaedic implants through its medical arm, Meshworks.

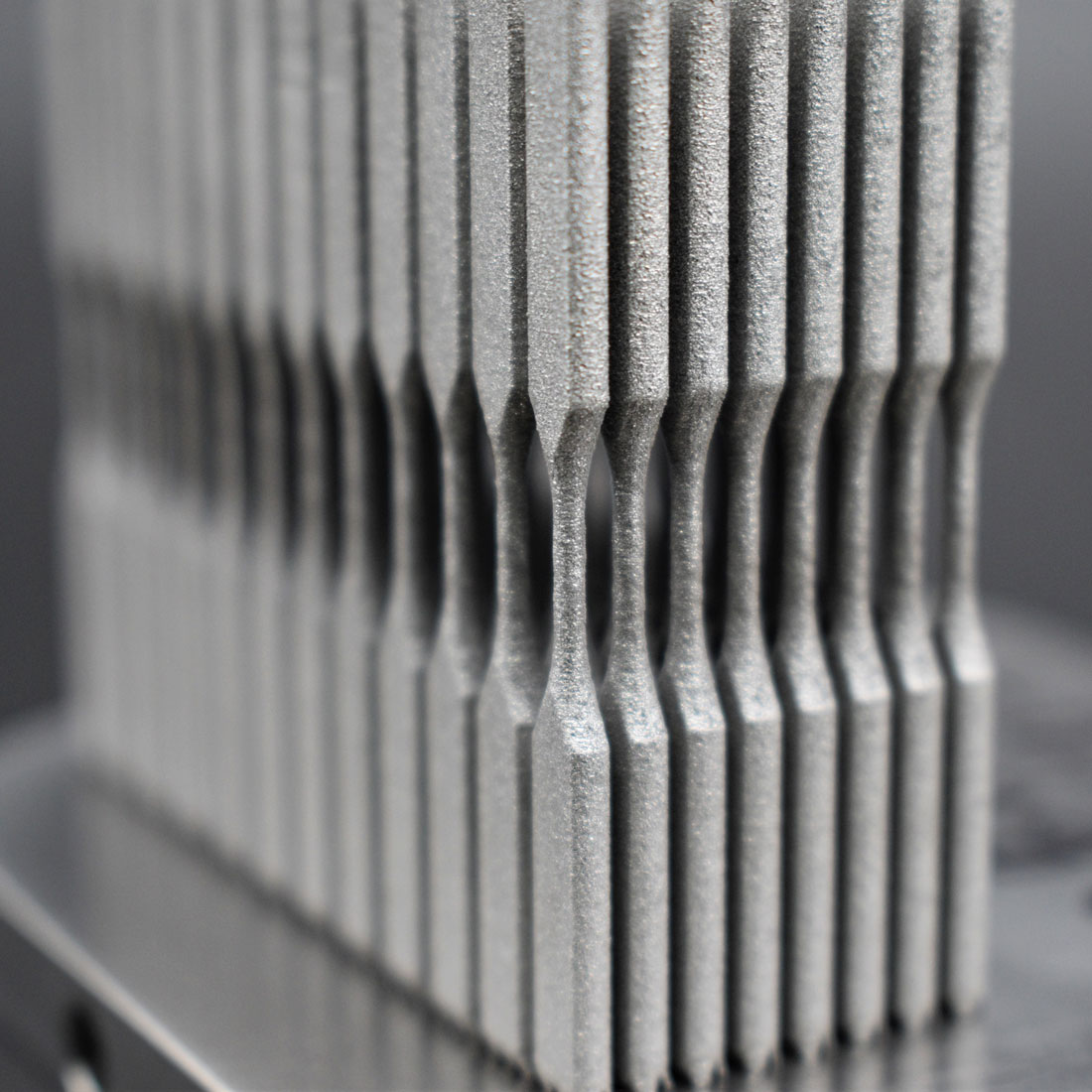

Meshworks combines intelligent orthopaedic design tools with unparalleled expertise in additive manufacturing for the production of patient-specific implants for bone reconstruction surgery. Custom implants provide a step-change in results for patients with complex cases, especially if standard, off-the-shelf implants are not suitable.

There is a strong clinical precedent for titanium implant scaffolds in bone reconstruction surgeries, and they typically give excellent clinical outcomes. However, for patients with complex bone conditions such as large bones or significant displacement, it can be difficult for surgeons to prescribe standard, off-the-shelf implants of the ideal size and shape for the defect. While some solutions exist for surgeons to customise existing implants, the design process can be daunting, and procurement can be prohibitively slow or expensive. Consequently, custom implants are often not considered even in cases where they could offer significant benefit.

The Meshworks design and production platform from Alloyed has been constructed in close collaboration with surgeons, incorporating an intuitive design process that can be used to plan the most complex cases. By combining advanced design tools with rapid, state-of-the-art additive manufacturing, Meshworks aims to reduce patient readmission and improve quality of life for patients with a broad range of bone conditions.